CNC machining pasina kupokana ndiyo inoraramisa indasitiri yekugadzira ine maapplication akaita seaerospace, michina yekurapa, uye zvemagetsi. Mumakore achangopfuura, kwave nekufambira mberi kunoshamisa mumunda weCNC machining zvinhu. Yavo yakakura portfolio ikozvino inopa musanganiswa wakakura wezvinhu zvivakwa, mutengo, uye aesthetics.

Muchinyorwa chino, isu tichanyura mune dzakasiyana nyika yeCNC zvinhu. Isu tichakupa iwe dhairekitori rakazara rekusarudza izvo zvinhu zvakanaka zveCNC machining, kusanganisira rondedzero yakadzama yezvinhu zvinowanzo shandiswa. Pamusoro pezvo, isu tichabata pane zvimwe zvisingazivikanwe zvinhu zvaungave usina kufunga nezvazvo.

Machining Environment

Izvo zvakakosha kufunga nezve machining nharaunda pakusarudza CNC zvinhu. Nekuti zvinhu zvakasiyana zvinobata zvakasiyana kune akasiyana machining mamiriro, sekumhanya kwekucheka, zvekushandisa, uye inotonhorera. Nzvimbo yekugadzira michina inosanganisira zvinhu zvakadai sekushisa, humidity, uye kuvapo kwezvinosvibisa.

Semuyenzaniso, zvimwe zvinhu zvinogona kunge zvine tsika yekurovera kana kutsemuka kana tembiricha yekugadzira yakakwira zvakanyanya, nepo vamwe vanogona kuwana yakawandisa maturusi kupfeka kana kumhanya kwekucheka kwakanyanya. Saizvozvo, kushandiswa kwezvimwe zvinotonhorera kana mafuta ekuzora kungave kuri madikanwa kuderedza kupisa uye kupokana panguva yekugadzira. Asi izvi zvinogona kunge zvisingaenderane nezvimwe zvinhu uye zvinogona kutungamira mukuora kana mamwe maitiro ekukuvadza.

Naizvozvo, kufunga nezvemamiriro ekugadzira michina kunogona kubatsira kuvandudza kugadzirwa, kuderedza mitengo, uye kuve nechokwadi chemhando yechigadzirwa chakapedzwa.

Chikamu Weight

Izvo zvakakosha kuti titarise chikamu chehuremu kuti ive nechokwadi chekudhura-kushanda, kuita, uye kugadzira. Zvikamu zvinorema zvinoda zvimwe zvinhu, izvo zvinogona kuwedzera mutengo wekugadzira. Pamusoro pezvo, zvikamu zvinorema zvingada yakakura uye yakasimba CNC michina kugadzira, izvo zvinowedzera mutengo uye nguva yekugadzira. Naizvozvo, kusarudza chinhu chine density yakaderera, senge aruminiyamu kana magnesium, inogona kubatsira kudzikisa huremu hwechikamu uye kudzikisa mutengo wekugadzira.

Kunze kwezvo, chikamu chehuremu chinogonawo kukanganisa kushanda kwechigadzirwa chekupedzisira. Semuenzaniso, mumashandisirwo emuchadenga, kuderedza huremu hwechikamu kunogona kuwedzera kushanda kwemafuta uye kunatsiridza kuita kwese. Mumashandisirwo emotokari, kuderedza huremu kunogonawo kuvandudza kushanda kwemafuta, pamwe nekuwedzera kukurumidza uye kubata.

Heat Resistance

Kupisa kupisa kunokanganisa zvakananga kugona kwechinhu kutsungirira tembiricha yakanyanya pasina kusangana nekukanganisa kukuru kana kukuvara. Munguva yeCNC machining process, zvinhu zviri kugadzirwa zvinosangana nekudziya kwakasiyana-siyana uye kutonhora kutenderera, kunyanya kana ichichekwa, kucherwa, kana kugayiwa. Aya matenderedzwa anogona kukonzera kupisa kwekuwedzera, kuputika, kana kuputika mumidziyo isingadziviriri kupisa.

Kusarudza CNC zvinhu zvine kunaka kupisa kupisa kunogona kubatsirawo kuvandudza machining maitiro uye kuderedza mutengo wekugadzira. Kana chinhu chikakwanisa kumira tembiricha yakakwira, inobvumira kukurumidza kucheka kumhanya uye kudzika kwakadzika. Izvi zvinounza mapfupi machining nguva uye kuderedzwa kupfeka pamidziyo.

Zvishandiso zvakasiyana zveCNC machining zvine mazinga akasiyana ekupisa kupisa, uye kusarudzwa kwezvinhu kunoenderana nekushandiswa kwakagadzirirwa kwechigadzirwa chakapedzwa. Zvishandiso zvakaita sealuminium nemhangura zvakakodzerwa nekupisa sinks uye thermal management application nekuda kwekunaka kwavo kwekushisa. Asi simbi isina tsvina uye titanium yakanakira aerospace uye zvikumbiro zvekurapa nekuda kwekunyungudika kwadzo kwakakwirira uye kushomeka kwekuora.

Electrical Conductivity uye Magnetic Zvinodiwa

Electrical conductivity chiyero chekugona kwechinhu kufambisa magetsi. MuCNC machining, zvinhu zvine high magetsi conductivity zvinofarirwa nekuti zvinogona kuburitsa kupisa zvakanaka. Izvi zvinonyanya kukosha kana uchigadzira simbi, sezvo kupisa kunogadzirwa panguva yekuita kunogona kuita kuti zvinhu zviome kana kutsvedza. Zvinhu zvine high conductivity yemagetsi, zvakadai semhangura nealuminium, zvinogona kunyatsopisa kupisa, izvo zvinobatsira kudzivirira nyaya idzi.

Magnetic zvivakwa zvakakoshawo pakusarudza CNC zvinhu, kunyanya kana uchishanda neferromagnetic zvinhu zvakaita sesimbi, nickel, uye cobalt. Zvinhu izvi zvine simba remagineti rinogona kukanganisa nzira yekucheka. Zvishandiso zvisiri-magineti, senge titanium uye simbi isina tsvina, inosarudzwa kune CNC machining. Nekuti ivo havana kukanganiswa neiyo magineti uye saka vanogadzira yakachena yekucheka.

Kuoma

Machinability inoreva nyore nyore kucheka, kudhiriwa, kana kuumbwa neCNC muchina chishandiso.

Kana CNC zvinhu zvanyanya kuoma, zvinogona kunetsa kucheka kana kuumba, izvo zvinogona kukonzera yakawandisa maturusi kupfeka, kuputswa kwemidziyo, kana kupera kwakashata kwepamusoro. Sezvineiwo, chinhu chakanyanya kupfava chinogona kukanganisa kana kutsauka pasi pesimba rekucheka, zvichikonzera kusarongeka kwema dimensional kana kupera kwepamusoro.

Naizvozvo, kusarudza chinhu cheCNC machining nekuomarara kwakakodzera kwakakosha kuti uwane yemhando yepamusoro, chaiyo yemuchina zvikamu. Pamusoro pezvo, kuoma kwezvinhu kunogona kukanganisa kukurumidza uye kushanda kweiyo machining process. Nekuti zvinhu zvakaoma zvinogona kuda kunonoka kucheka kumhanya kana mamwe ane simba ekucheka maturusi.

Surface Finish

Kupera kwepamusoro kunokanganisa kushanda kwechigadzirwa chekupedzisira uye chitarisiko. Semuyenzaniso, chikamu chine hutsinye hwepamusoro pekupedzisira chinogona kusangana nekukweshana kwakawanda, izvo zvinogona kutungamira mukupfeka nguva isati yakwana uye kukundikana. Kune rumwe rutivi, chikamu chine kutsetseka kwepamusoro kupedzisa kuchava nekukwesha kushoma, zvichikonzera kuvandudzwa kwekuita uye hupenyu hurefu. Pamusoro pezvo, kupedzisa kwepamusoro kunoitawo basa rakakosha mune aesthetics. Iyo yakakwenenzverwa pamusoro pekupedzisira inogona kuvandudza kutaridzika kwechikamu uye kuita kuti iwedzere kukwezva vatengi.

Naizvozvo, pakusarudza zvinhu zveCNC machining, zvakakosha kuti utarise iyo yepamusoro pekupedzisira zvinodiwa kune yekupedzisira chigadzirwa. Zvimwe zvinhu zviri nyore kumichina kusvika pakutsetseka kwepamusoro pekupedzisira pane zvimwe. Semuenzaniso, simbi dzakaita sealuminium nendarira zviri nyore kugadzira muchina kusvika kumagumo akatsetseka. Mukupesana, zvinhu zvakaita senge kabhoni faibha uye fiberglass zvinogona kunetsa kumuchina, uye kuwana yakatsetseka pamusoro pekupedzisira kungada maturusi ehunyanzvi uye matekiniki.

Aesthetics

Kana CNC machining purojekiti yako yakarongedzerwa kugadzira chigadzirwa chinozoshandiswa munzvimbo yepamusoro-yekupedzisira yekutengesa, aesthetics ingave yakakosha chinhu. Zvinhu zvacho zvinofanirwa kunge zvichiyevedza, zvine mavara anoyevedza, ruvara, uye kupera kwepamusoro. Inofanirwa zvakare kuve inokwanisa kukwenenzverwa, kupendwa, kana kupedzwa kuti uwane chitarisiko chaunoda.

Pamusoro pezvo, mumaindasitiri akadai semotokari uye aerospace, aesthetics inogona kuve chiratidzo chemhando yechigadzirwa uye kutarisisa kwemugadziri kune zvakadzama. Izvi zvinonyanya kukosha mumotokari dzemhando yepamusoro, uko vatengi vanobhadhara mari yepamusoro yezvinhu zvemhando yepamusoro uye kupera.

Application

Iko kushandiswa kwekupedzisira kwechigadzirwa ndiyo yekupedzisira-mugadziri wesarudzo. Izvo zvambotaurwa zvinoumba chikamu chidiki chezvikonzero zvese izvo munhu anofunga asati apedzisa CNC zvinhu. Zvimwe zvinhu zvinofambiswa nekushandisa zvinogona kusanganisira zvinobatika zvinobatika senge material machinability, chemical reactivity, adhesiveness, kuwanikwa kwezvinhu, hupenyu hwekuneta, nezvimwe.

Kana zvasvika pakusarudza zvinhu zvakakodzera zveCNC machining, iko kushandiswa kwechigadzirwa chakapedzwa chinhu chakakosha kufunga. Zvishandiso zvakasiyana zvine maitiro akasiyana, sekuoma, kusimba kwesimba, uye ductility. Izvi zvivakwa zvinopesvedzera maitirwo anoita chinhu pasi pemamiriro chaiwo uye kuona kukodzera kwezvinhu zvekushandisa kwakasiyana.

Semuenzaniso, kana chigadzirwa chakapedzwa chakagadzirirwa kushandiswa munzvimbo yepamusoro-soro, zvinhu zvakadai sealuminium kana mhangura zvingava sarudzo iri nani nekuda kwepamusoro-soro yekupisa uye kuramba kukuvadza kupisa.

Budget

Budget chinhu chakakosha kufunga nezvezvikonzero zvakawanda. Chekutanga, mutengo wemidziyo unogona kusiyanisa zvakanyanya zvichienderana nerudzi uye huwandu hunodiwa. Nepo mamwe masimbi emhando yepamusoro angave achidhura, mapurasitiki kana macomposites anogona kudhurika. Kuisa bhajeti rezvishandiso kuchabatsira kudzikisira sarudzo dzako uye kutarisa pazvinhu zviri mukati memutengo wako.

Chechipiri, machining mitengo yeCNC inogona kudhura uye inopedza nguva. Mutengo wekugadzira unoenderana nerudzi rwezvinhu, kuoma kwechikamu, uye inodiwa michina. Kusarudza zvinhu zvakachipa kumuchina kunogona kuchengetedza mutengo wekugadzira wakaderera.

Chekupedzisira, kusarudza zvinhu zviri mukati mebhajeti yako zvinogona kukanganisa kunaka kwechigadzirwa. Zvishandiso zvakachipa zvinogona kuve zvakanyanya kukanganiswa kana kusasimba pane zvemhando yepamusoro. Naizvozvo, kuseta bhajeti uye kusarudza zvinhu zvemhando yepamusoro mukati mebhajeti zvinovimbisa kuti chigadzirwa chakapedzwa chakasimba uye chemhando yepamusoro.

Izvo Zvakanakisa Zvishandiso zveCNC Machining Projects

Zvino, ngatienderere mberi kune chikamu chinotevera chehurukuro yedu: marudzi eCNC machining zvinhu. Tichakurukura zvakadzama masimbi enguva dzose uye mapurasitiki. Gare gare, isu tichashandura tarisiro yedu kune zvimwe zvisinganyatso zivikanwa CNC zvinhu.

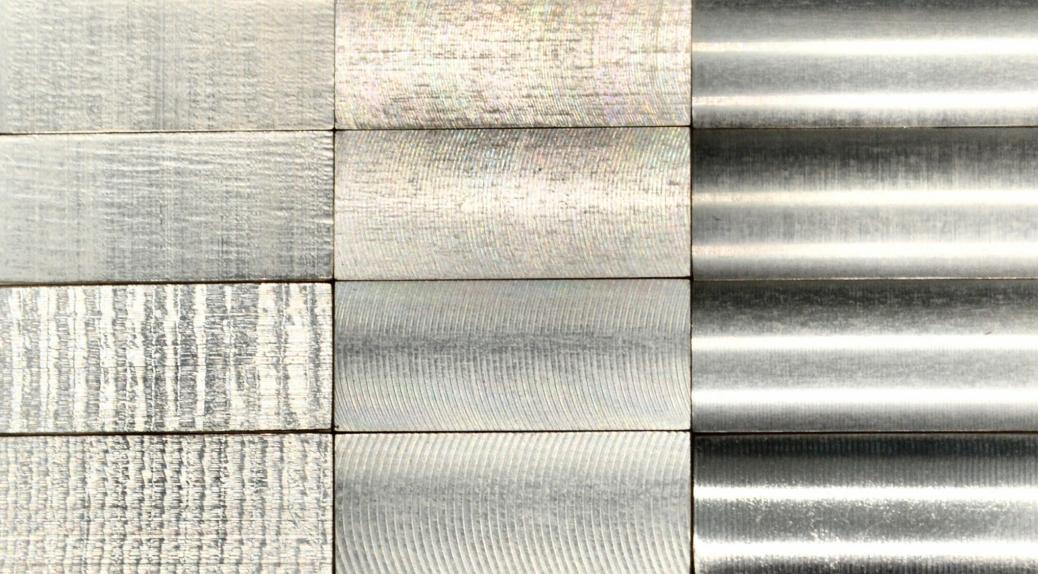

Metal CNC Zvishandiso

Simbi ndiyo inonyanya kuzivikanwa zvinhu pakati peCNC machined zvikamu. Vanopa huwandu hwakasiyana hwezvivakwa zvakanaka senge kusimba kwepamusoro, kuomarara, kupisa kwemafuta, uye magetsi conductivity.

Aluminium (6061, 7075)

Aluminium inoonekwa zvakanyanya seimwe yeanonyanya kushandiswa uye akakosha zvinhu muCNC machining. Iyo ine yakasarudzika simba-ku-huremu reshiyo, huremu hunhu, corrosion resistance, uye inoyevedza silvery chitarisiko. Saka, aluminium inonyanya kudiwa kuti ishandiswe mumhando dzakasiyana dzekushandisa. Pamusoro pezvo, yakanakira kupisa uye magetsi zvimiro zvinoita kuti ive yakanakira kushandiswa mumhando yemagetsi uye yekupisa manejimendi application.

Kuenzaniswa nedzimwe CNC simbi, dzakadai titanium nesimbi, aruminiyamu iri nyore kugadzira muchina, izvo zvinoita kuti ive yakakurumbira sarudzo kune vanogadzira. Nekudaro, zvinofanirwa kucherechedzwa kuti aluminium haisi iyo yakachipa zvinhu zviripo. Uye inodhura kudarika zvimwe zvinhu, zvakadai sesimbi isina tsvina.

Iwo emhando yepamusoro 6061 uye 7075 mamakisi ealuminium anonyanya kufarirwa kushandiswa mumafuremu emuchadenga, zvikamu zveinjini yemotokari, uye midziyo yemitambo isingaremi. Nekudaro, kuita zvakasiyana-siyana kwealuminium kunoreva kuti inoshandiswa mune mamwe maindasitiri mazhinji uye maapplication, kusanganisira kuvaka, kurongedza, uye zvemagetsi zvevatengi.

Simbi isina Stainless (316, 303, 304)

Simbi isina tsvina inouya mumagiredhi akawanda. Kazhinji, zvakadaro, ine simba repamusoro uye kuoma, kusapfeka, uye kusagadzikana kwekuora, uye ine inopenya senge aluminium. Uyezve, iri pakati pematare epakati-mutengo. Nekudaro, iyo yakaoma-ku-muchina CNC zvinhu nekuda kwekuoma kwayo.

316 SS inobatsira muzvishandiso zvemugungwa, midziyo yekurapa, uye nzvimbo dzakavharirwa kunze nekuda kwekugona kwayo kushingirira kupisa nekuora. 303 ne314 vanogovana nziyo dzakafanana uye dzinowanzochipa uye dzinogoneka kupfuura 316. Kunyanya kushandiswa kwavo kunosanganisira mabhaudhi, screws, bushings, nezvimwewo), zvikamu zvemotokari, uye midziyo yemumba.

Carbon Steel uye Alloy Steel

Carbon simbi uye ane hukama alloys anopa simba rakanakisa uye machinability, zvichiita kuti ive yakanakira kushandiswa mune akawanda maapplication. Izvo zvakare zvinopindirana neakasiyana-siyana ekurapa kupisa maitiro, zvichiwedzera kusimudzira yavo michina. Uyezve, kabhoni simbi isingadhure zvichienzaniswa nemamwe CNC simbi.

Nekudaro, zvakakosha kuti ticherechedze kuti kabhoni simbi uye alloys ayo haagarike nekuora, kusiyana nezvinhu zvakaita sesimbi isina tsvina kana aluminium. Pamusoro pezvo, chitarisiko chavo chakakasharara chinogona kunge chisina kukodzera kune aesthetic application.

Zvakangodaro, kabhoni simbi uye alloys ayo ane akawanda anoshanda maapplication, anosanganisira ma mechanical fasteners uye zvimiro zvakaita sematanda. Kunyangwe zvisingakwanisi, zvinhu izvi zvinoramba zvakakurumbira sarudzo kune akawanda maindasitiri nekugadzira maapplication nekuda kwesimba rawo, kugona, uye machinability.

Brass

Brass isimbi inoshanda zvakasiyana-siyana inozivikanwa nekunaka kwayo machinability, corrosion resistance, uye thermal uye magetsi conductivity. Iyo zvakare inozvirumbidza inoyevedza chitarisiko nekuda kwemhangura yayo yemukati, pamwe neakanakisa friction yepasi.

Brass inowana akawanda maapplication mumaindasitiri akasiyana. Semuenzaniso, inowanzoshandiswa muzvigadzirwa zvevatengi, zvitsigiro zvakadzika-simba, pombi dzemvura, uye zvigadzirwa zvemagetsi. Zvimiro zvayo zvinoita kuti ive sarudzo yakanaka yekugadzira zvinhu zvinoda kusimba uye kusimba uku uchichengeta inoyevedza kukwezva.

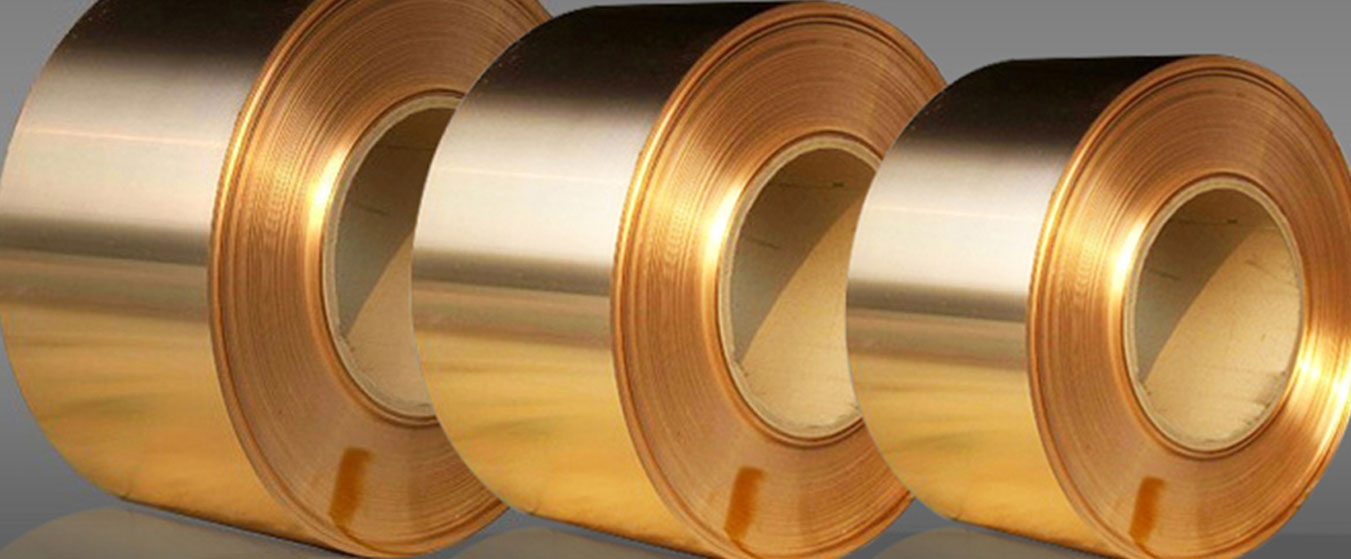

Mhangura

Mhangura inozivikanwa nekunaka kwayo magetsi nekupisa. Nekudaro, zvinogona kunetsa kumashini nekuda kwekukwirira kwayo. Izvi zvinogona kukonzera kunetsa mukugadzira machipisi panguva yeCNC machining. Mukuwedzera, mhangura inowanzoita ngura, iyo inogona kuva nehanya mune dzimwe nzvimbo.

Pasinei nematambudziko aya, mhangura inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana, anosanganisira waya dzemagetsi, zvigadzirwa zvemagineti, uye kugadzira zvishongo. Yayo yakanakisa conductivity zvimiro inoita kuti ive sarudzo yakanakira yemagetsi uye zvemagetsi zvikumbiro, nepo malleability uye aesthetic kukwezva kunoita kuti ive sarudzo yakakurumbira muindasitiri yezvishongo.

Titanium

Titanium alloys anozivikanwa nekuda kwesimba rawo-kune-uremu reshiyo, zvichiita kuti dzisaremekedze uye dzisimbe panguva imwe chete. Iwo zvakare anodzivirira-kuora uye ane yakanaka kupisa conductivity. Pamusoro pezvo, titanium ndeye biocompatible, saka inokodzera biomedical application.

Zvisinei, pane zvimwe zvipingamupinyi pakushandisa titanium. Iine hutsika husina kunaka hwemagetsi uye inonetsa kuigadzira. Yenguva dzose HSS kana isina kusimba carbide cutters haina kukodzera kuigadzira, uye chinhu chinodhura chekushandisa mukugadzira CNC.

Kunyange zvakadaro, titanium chinhu chakakurumbira cheCNC machining, kunyanya chepamusoro-chinoita nzvimbo dzemuchadenga, zvikamu zvemauto, uye zvigadzirwa zvebiomedical semaimplants.

Magnesium

Magnesium isimbi inobatanidza simba nehuremu hushoma. Hunhu hwayo hwakanakisa hwekupisa hunoita kuti ive yakakodzera kushandiswa munzvimbo dzinopisa zvakanyanya, senge mumainjini. Huremu hwayo hunobvumira kugadzirwa kwemotokari dzakareruka uye dzinoshandisa mafuta akawanda.

Nekudaro, magnesium inozivikanwa zvakare nekupisa kwayo, izvo zvinogona kuita kuti ive chengetedzo kunetseka mune mamwe maapplication. Pamusoro pezvo, haina kusimba nekuora semamwe simbi, senge aluminium, uye inogona kudhura muchina.

Plastiki CNC Zvishandiso

Iye zvino tichakurukura CNC mapurasitiki. Kunyangwe zvinhu zvakawanda zvepurasitiki zvisingagoneki nekuda kwekudzikama kwadzo uye kunyungudika, isu takasarudza boka diki rine hupamhi hweCNC application.

Acetal (POM)

Acetal ipurasitiki inosiyana-siyana yeCNC ine huwandu hwezvinhu zvinodikanwa. Iyo inozvirumbidza yakanakisa kuneta uye kukanganisa kupikisa, kusimba kwakanaka, uye yakaderera friction coefficients. Kunze kwezvo, inoshingirira kunyorova, izvo zvinoita kuti ive sarudzo yakanaka kwazvo yekushandisa munzvimbo dzine unyoro.

Imwe yemabhenefiti akakosha eacetal kuomarara kwayo, izvo zvinoita kuti zvive nyore kumichina nehukuru hukuru hwechokwadi. Izvi zvinoita kuti ive sarudzo yakakurumbira yekushandisa muzvinhu chaizvo zvakaita semabheya, magiya, uye mavharuvhu. Nekuda kweakanakisa emuchina zvivakwa uye kuramba kwakanyanya kune zvakatipoteredza zvinhu, Acetal isarudzo yakavimbika kune akasiyana maindasitiri, akadai semotokari, aerospace, uye zvinhu zvevatengi.

Acrylic (PMMA)

Acrylic chinhu chinowanzo shandiswa chinogona kushanda sechinotsiva girazi nekuda kwehunhu hwayo hunodiwa. Iyo ine kuomarara kwakanaka uye kujeka kwemaziso, ichiibvumira kuti ishandiswe mumashandisirwo apo kuona-kuburikidza nepamusoro kwakakosha. Acrylic components inopa inoyevedza uye inoshanda imwe nzira kune girazi, ine yakanaka yekuona kujeka uye yakakwirira dhigirii rekugara.

Nepo acrylic aine zvimwe zvinogumira, senge kukanganisa kwayo kutsemuka uye kupfava kwemafuta, inoramba iri chinhu chakakurumbira cheCNC machining nekuda kwekuita kwayo uye nyore kushandisa. Nekugona kugadzira chaiwo, emhando yepamusoro zvikamu, acrylic isarudzo yakanakisa yeakasiyana maapplication. Malenzi, akavharirwa akajeka, midziyo yekuchengetera chikafu, uye zvinhu zvekushongedza ingori mienzaniso mishoma.

Polycarbonate (PC)

Polycarbonate (PC) ipurasitiki yakakurumbira inoshandiswa kuCNC machining nekuda kweiyo yakasarudzika seti yezvivakwa. Iri pachena zvakanyanya, zvichiita kuti ive chinhu chakanakira kushandiswa mune zvigadzirwa zvinoda kujekeswa, senge magirazi ekuchengetedza, midziyo yekurapa, uye zvemagetsi zviratidziro. Uyezve, ine yakanaka yekupisa inodzivirira saka yakakodzera kushandiswa mune yakakwirira-tembiricha application.

Nekudaro, kugona kwayo kukwenya uye kushomeka kweUV kuramba kunogona kudzikisira kushandiswa kwayo mune mamwe maapplication. Kugara pachiedza chezuva kwenguva refu kunogona kuita kuti riite yero uye riite brittle. Izvi zvinogona kudzikisira kushandiswa kwayo mumashandisirwo ekunze kunze kwekunge yakagadziridzwa neUV stabilizer.

Kumwe kushandiswa kwakajairwa kwePC kuri mukugadzirwa kwemagirazi ekuchengetedza uye nhovo dzechiso, uko kupikisa kwayo uye kujeka kunoita kuti ive sarudzo yakanaka. PC inoshandiswawo mukugadzira zvikamu zvemotokari, zvinhu zvemagetsi, uye michina yekurapa.

Polypropylene (PP)

Polypropylene i polymer inoshanda zvakasiyana-siyana ine akawanda mabhenefiti, anosanganisira yakakwira makemikari kuramba uye kuneta simba. Iyo zvakare yekurapa-giredhi zvinhu, uye inogadzira yakatsetseka yekumusoro kupera kana CNC machining. Zvisinei, imwe yezvipimo zvayo ndeyokuti haigoni kumira kutonhora kwakanyanya, sezvo inowanzoita kupfava uye nduru panguva yekucheka, izvo zvinoita kuti zviome zvishoma kumuchina.

Polypropylene inoramba iri sarudzo yakakurumbira kune akasiyana maapplication. Hunhu hwayo hwakanaka hunoita kuti ive yakakodzera kugadzira magiya uye zvigadzirwa zvekurapa.

ABS

ABS inodhura zvakanyanya-inoshanda epurasitiki zvinhu zvakanyatsoenderana neCNC machining nekuda kwekunaka kwayo machina, kusimba kwesimba, kukanganisa kupikisa, uye makemikari kuramba. Uyezve, inogona kuve yakapendwa nyore, ichiita kuti ive yakakodzera kune maapplication uko aesthetics yakakosha.

Nekudaro, ABS haina kukodzera kushandiswa munzvimbo dzinopisa zvakanyanya uye haina-biodegradable. Kunze kwezvo, inoburitsa furo isingafadzi kana yapiswa, inogona kunetsa muchitoro cheCNC.

ABS ine akawanda maapplication uye inowanzoshandiswa mukudhinda 3D uye jekiseni kuumba, kazhinji nekumashure-kugadzirisa uchishandisa CNC machining. Inowanzoshandiswa kugadzira zvinhu zvemotokari, uye zvivharo zvekudzivirira, uye nekukurumidza prototyping.

Nylon

Nylon chinhu chakasiyana-siyana chine simba rakanyanya kusimba, kuomarara, uye kukanganisa kupikisa. Inogona kushandiswa mumhando dzakasiyana-siyana dzakaumbwa, dzakadai segirazi-fiber-yakasimbiswa naironi, uye ine yepamusoro yepamusoro lubrication kugona. Nekudaro, hazvikurudzirwe kushandiswa munzvimbo dzakanyorova.

Nylon inonyanya kunyatsokodzera zvikumbiro zvinoda kuchengetedzwa kubva kumasimba anopokana. Izvi zvinosanganisira zvinhu zvakaita semagiya, nzvimbo dzinotsvedza, mabhengi, uye sprockets. Nesimba rayo repamusoro uye zvimiro zvekuzora, nylon isarudzo yakakurumbira kune akawanda maindasitiri uye ane chekuita nemitambo zvigadzirwa.

UHMW-PE

UHMWPE chinhu chakakurumbira nekuda kwehunhu hwayo hwakasiyana, zvinosanganisira kuomarara kwakanyanya, abrasion uye kupfeka kuramba uye kusimba. Nekudaro, kusagadzikana kwayo kwekupisa panguva yekugadzira kunoita kuti zviome kumushini.

Kunyangwe kuoma kwayo mukugadzira, UHMWPE chinhu chakanakisa cheCNC machining enzvimbo inotsvedza mumabhengi, magiya, uye rollers. Zvimiro zvaro zvakatanhamara zvinoita kuti ive yakanaka kune maapplication uko yakakwirira kupfeka kuramba uye kusimba kunodiwa. Kana ikagadzirwa nemazvo, UHMWPE inogona kupa kuita kwakanakisa uye hupenyu hurefu kana uchienzaniswa nezvimwe zvinhu.

Zvimwe Zvishandiso

CNC machining inowanzoshandisa simbi nemapurasitiki, asi inogonawo kushanda nezvimwe zvinhu zvakawanda, kusanganisira izvo zvakanyorwa pazasi.

Foam

Mafuro imhando ye CNC zvinhu zvinoonekwa nemuviri wakasimba une mavhodhi akazadzwa nemhepo. Ichi chimiro chakasiyana chinopa furo chimiro chinozivikanwa uye kureruka kunoshamisa. Mamwe mafuro akakwira-density, akadai se polyurethane foam uye Styrofoam, anogona kugadzirwa nyore nyore nekuda kwekuoma kwawo, simba, kureruka, uye kusimba.

Foams 'lightweight nature inovaita yakanakisa sarudzo yekudzivirira kurongedza. Kushanda kwavo kwakasiyana-siyana mukugadzirwa mumhando dzakasiyana-siyana uye hukuru hunoita kuti zvive zvakakosha pakugadzira zvinhu zvekushongedza. Kunze kwezvo, zvimiro zvavo zvekudzivirira zvinovaita sarudzo yakakurumbira yekudzivirira kupisa muzvivakwa, mafiriji mayunitsi, uye zvimwe zvinoshandiswa uko kunodzora tembiricha kwakakosha.

Wood

Huni chinhu chakashandiswa zvakanyanya kune CNC machining nekuda kwekureruka kwayo kwekugadzira, simba rakanaka uye kuoma, uye hupamhi hwemhando dziripo. Mukuwedzera, huni inhengo yehupenyu uye haina kukanganisa kune zvakatipoteredza. Nekuda kwekusiyana-siyana uye kukwezva kukwezva, huni isarudzo yakakurumbira yefenicha, yekushongedza imba, uye mapurojekiti eDIY.

Zvisinei, kugadzira huni kunobudisa huruva yakawanda, iyo inogona kuisa njodzi dzehutano kuvashandi. Naizvozvo, zvakakosha kuti maworkshops ekugadzira huni ave nemafambisirwo akakodzera ekutonga kweswarf munzvimbo.

Composites

Kompositi zvinhu zvinoumbwa nezvikamu zviviri kana kupfuura zvinobatanidzwa pamwe chete nepakati pekubatanidza. Zvakajairika composite zvinhu zvinoshandiswa muCNC machining zvinosanganisira kabhoni faibha, plywood, fiberglass, nezvimwe. Zvishandiso izvi zvine maapplication mumaindasitiri akasiyana, akadai semotokari, ndege, mitambo, uye zvekurapa.

Machining composite inogona kunetsa nekuda kwezvinhu zvakati wandei. Izvo zvinoumba zvinhu mumacomposites zvinogona kuve neakasiyana emuchina zvimiro uye mafomu, senge fiber, shards, kana mahwendefa. Zvakare, iyo yekubatanidza yepakati pachayo inogona kuve neyakasarudzika zvivakwa zvinoda kuverengerwa panguva yekugadzira machining.

Usakanganwa Kufunga Zvinogona CNC Zvishandiso

Iyo yakapfuma yakasiyana-siyana muCNC machining zvinhu dzimwe nguva inogona kukonzera kuvhiringidzika kupfuura kubatsirwa. Iyo inyaya yakajairika kufuratira zvingangoita CNC zvinhu kupfuura zvakajairwa simbi nemapurasitiki.

Kuti ikubatsire kutarisa mufananidzo muhombe paunenge Uchigadzira Kugadzira, pazasi pane rondedzero pfupi yemapoinzi ekufunga usati wapedzisa zvigadzirwa zvepurojekiti yako!

Sarudza Zvisiri-Simbi Zvishandiso: Pane akati wandei apo zvisiri zvesimbi zvinhu zvakaenzana zvinotsiva simbi. Mapurasitiki akaoma seABS kana UHMW-PE akasimba, akasimba, uye anogara, semuenzaniso. Macomposites akadai sekabhoni faibha anoonekwawo seakakwirira kune simbi dzakawanda dzinoita zvakanakisa.

Funga nezvePhenolics: Phenolics imhando yezvinodhura-zvinoshanda zvinoumbwa zvinhu zvine kusimba kwakanyanya uye pamusoro pezvimiro. Iwo ari nyore kumichina uye anogona kucheka nekumhanya zvinoshamisa, kuchengetedza nguva nemari.

Ziva Mapurastiki Akasiyana: Kuve neruzivo nezve yakazara portfolio yepurasitiki CNC machining zvinhu hunyanzvi hunofanirwa-kuva nevagadziri. CNC mapurasitiki akachipa, ari nyore kumichina, uye anouya mumhando dzakasiyana dzezvinhu zvisingagoni kufuratirwa.

Sarudza Iko Kurudyi Pakati PeMafuro Akasiyana: Tichitaura kune chikamu chiri pamusoro pamusoro pemafuro, tinoda kusimbisa kuti ine zvakawanda zvinogoneka se CNC zvinhu. Kunyangwe zvimwe zvikamu zvemuchina weCNC zvave kugadzirwa kubva kumafuro esimbi! Dzidza akasiyana CNC mafuro kuti uone kuti ndeipi inokodzera maapplication ako zvakanyanya.

Yakasiyana CNC Machining Projects uye Zvishandiso, Imwe Tsime

Dhizaini yekugadzira chinhu chakakosha cheindasitiri yemazuva ano. Sezvo sainzi yenyama yave kufambira mberi, CNC machining yawedzera kuvimba nekufunga zvinhu kusarudzwa. KuGuan Sheng, isu tine hunyanzvi muCNC machining masevhisi, anosanganisira CNC kugaya uye kutendeuka, uye tinopa huwandu hwakakura hwezvinhu, kubva kumatare anotsvakwa kusvika kumapurasitiki emhando yepamusoro. Yedu 5-axis machining masimba, akasanganiswa nechikwata chedu chine ruzivo, anotibvumira kupa husingaenzaniswi nemazvo uye mhando kune vatengi vedu.

Isu takazvipira kupa yakasarudzika yevatengi sevhisi uye takazvipira kubatsira vatengi vedu kuderedza mutengo uye kuzadzisa zvinangwa zvavo. Yedu tekinoroji timu iripo kuti ikubatsire iwe mukusarudza zvakanakisa zvigadzirwa zvepurojekiti yako uye inogona kupa zano renyanzvi pasina muripo. Kunyangwe iwe uchida tsika dzeCNC dzakagadzirwa zvikamu kana uine chaiyo purojekiti mupfungwa, tiri pano kuti tikubatsire nhanho dzese dzenzira.

Nguva yekutumira: Jul-07-2023