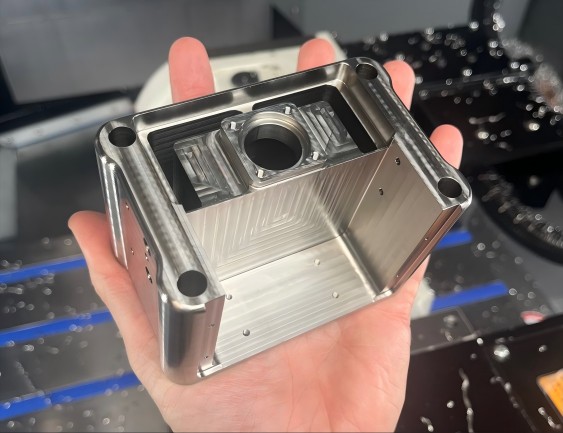

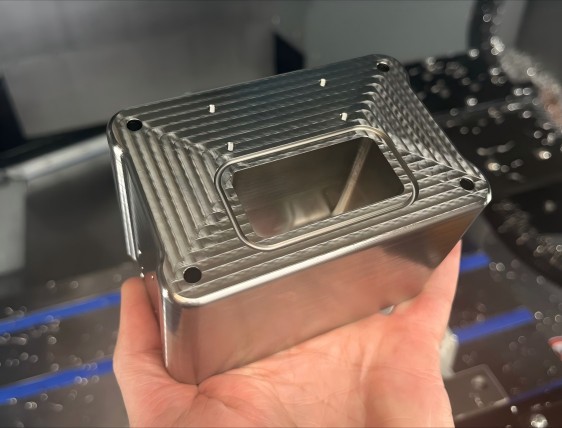

Munguva ichangopfuura takagadzira bheti yezvikamu zvesimbi isina tsvina.Chinodiwa chekururama chakakwirira kwazvo, chinoda kusvika ± 0.2μm. Zvinhu zvesimbi isina tsvina zvakaoma. MuCNC machining eStainless simbi zvinhu, matanho anowirirana anogona kutorwa kubva kune pre-processing kugadzirira, kugadzirisa maitiro ekugadzirisa uye post-processing kuvandudza kururamisa kwekugadzirisa. Inotevera ndiyo chaiyo nzira:

Pre-processing kugadzirira

• Sarudza chigadziro chakakodzera: maererano nemaitiro ezvigadzirwa zvesimbi zvisina tsvina, zvakadai sekuoma kwakakwirira, kuoma, nezvimwewo, sarudza chigadziro chine kuoma kwepamusoro, kupfeka kwepamusoro uye kumira kwakanaka kwekunamatira, zvakadai se tungsten cobalt carbide zvishandiso kana midziyo yakavharidzirwa.

• Gadzirisa kuronga kwemaitiro: gadzira nzira dzakadzama uye dzinonzwisisika dzekugadzirisa, kuronga zvine musoro roughing, semi-kupedzisa uye kupedza maitiro, uye siya muganhu wekugadzirisa we0.5-1mm yekuzotevera yakakwirira-chaiyo yekugadzirisa.

• Gadzirira zvivharo zvemhando yepamusoro: Iva nechokwadi cheunifomu yemhando yezvinhu zvisina chinhu uye hapana kukanganisa kwemukati kuderedza machining accuracy zvikanganiso zvinokonzerwa nechinhu chacho pachako.

Process control

• Gadzirisa zvidimbu zvekucheka: Sarudza zvakakodzera kutema zvigadziro kuburikidza nekuedza uye ruzivo rwekuunganidza. Kazhinji kutaura, kushandiswa kwekudzika kwekucheka kumhanya, kudya zvine mwero uye kudzika kudiki kwekucheka kunogona kunyatso kudzikisa kupfeka kwechishandiso uye machining deformation.

• Kushandiswa kwemafuta ekuzora kwakakodzera: kushandiswa kwemvura yekucheka ine kutonhora kwakanaka uye lubrication zvinhu, zvakadai semulsion ine yakanyanyisa kudzvinyirira additives kana synthetic yekucheka mvura, inogona kuderedza kupisa kwekucheka, kuderedza kupesana pakati pechishandiso uye workpiece, inhibisa kugadzirwa kwechiputi tumors, nokudaro kuvandudza kunyatsogadziriswa kwekugadzirisa.

• Tool nzira optimization: Panguva yepurogiramu, nzira yezvishandiso inogadziriswa, uye inonzwisisika yekucheka maitiro uye trajectory inogamuchirwa kudzivirira kutendeuka kwakapinza kwechishandiso uye nguva dzose kukurumidza uye kuderedza, kuderedza kushanduka kwekucheka simba, uye kuvandudza kunaka uye kurongeka kwepamusoro pemachining.

• Kuzadzikiswa kwekutsvaga kwepaIndaneti uye kubhadhara: yakagadzirirwa neIndaneti yekuona hurongwa, nguva chaiyo yekutarisa kwehukuru hwebasa uye zvikanganiso zvechimiro mukugadzirisa, kugadziriswa panguva yakakodzera kwechigadziro chekushandisa kana kugadzirisa zvigadziro maererano nemigumisiro yekuona, kukanganisa kukanganisa.

post-processing

• Chiyero chakanyatsojeka: Shandisa CMM, profiler uye imwe midziyo yekuyera yakarurama kuti uenzanise zvakakwana workpiece mushure mekugadzirisa, kuwana saizi yakarurama uye data yechimiro, uye kupa hwaro hwekuongorora kwakanyatsojeka uye kutonga kwehutano.

• Kukanganisa kuongorora uye kugadzirisa: Maererano nemigumisiro yekuyera, ongorora zvikonzero zvekukanganisa kwekugadzira, zvakadai sekupfeka kwechishandiso, kucheka simba deformation, thermal deformation, nezvimwewo, uye tora matanho akakodzera ekugadzirisa nekuvandudza, sekutsiva maturusi, kugadzirisa teknolojia yekugadzirisa, kugadzirisa maparameter emuchina, nezvimwewo.

Nguva yekutumira: Zvita-20-2024