Chiratidziro chakajairwa cheCNC machining, nguva zhinji, chinosanganisira kushanda nesimbi yekushanda. Nekudaro, kwete chete iyo CNC machining inoshanda zvakanyanya kumapurasitiki, asi epurasitiki CNC machining ndeimwe yeakajairika machining maitiro mumaindasitiri akati wandei.

Kugamuchirwa kwemapurasitiki machining senzira yekugadzira imhaka yehuwandu hwakawanda hwepurasitiki CNC zvinhu zviripo. Uyezve, nekuunzwa kwekombuta nhamba yekudzora, maitiro anova akanyanya, nekukurumidza, uye akakodzera kugadzira zvikamu zvine kushivirira kwakasimba. Yakawanda sei iwe yaunoziva nezve epurasitiki CNC machining? Ichi chinyorwa chinokurukura zvinhu zvinoenderana nemaitiro, maitiro aripo, uye zvimwe zvinhu zvinogona kubatsira chirongwa chako.

Plastiki yeCNC Machining

Mazhinji machinable epurasitiki akakodzera kugadzira zvikamu uye zvigadzirwa akati wandei maindasitiri anogadzira. Kushandiswa kwavo kunoenderana nezvavanoita, nemamwe mapurasitiki anogadzirwa, akadai senaironi, ane akanakisa emuchina zvivakwa zvinovatendera kutsiva simbi. Pazasi pane akajairika mapurasitiki etsika epurasitiki machining:

ABS:

Acrylonitrile Butadiene Styrene, kana ABS, chinhu chakareruka cheCNC chinozivikanwa nekuramba, simba, uye kukwirira machinability. Kunyange zvazvo ichizvikudza zvakanaka zvemuchina, kudzikama kwayo kwekemikari kunoonekwa mukubatikana kwayo nemafuta, madoro, nezvimwe zvinonyungudutsa makemikari. Zvakare, kugadzikana kwekupisa kweiyo ABS yakachena (kureva, ABS isina zvinowedzerwa) yakaderera, sezvo polymer yepurasitiki ichapisa kunyangwe mushure mekubvisa murazvo.

Pros

Iyo ine huremu pasina kurasikirwa kwayo kwemagetsi simba.

Iyo yepurasitiki polymer inogoneka zvakanyanya, ichiita kuti ive yakakurumbira kukurumidza prototyping zvinhu.

ABS ine yakaderera kunyunguduka poindi yakakodzera (izvi zvakakosha kune mamwe anokurumidza prototyping maitiro senge 3D kudhinda uye jekiseni molding).

Iine simba repamusoro-soro.

ABS ine kusimba kwepamusoro, zvinoreva hupenyu hurefu.

Zvinokwanisika.

Cons

Inoburitsa utsi hwepurasitiki hunopisa kana huchipisa.

Unoda kufefeterwa kwakakodzera kudzivirira kuungana kwemagasi akadaro.

Iyo ine yakaderera kunyungudika iyo inogona kukonzera deformation kubva pakupisa kunogadzirwa nemuchina weCNC.

Applications

ABS inozivikanwa kwazvo engineering thermoplastics inoshandiswa nevakawanda vanokurumidza prototyping masevhisi mukugadzira zvigadzirwa nekuda kwehunhu hwayo hwakanaka uye kugona kwayo. Inoshanda mumaindasitiri emagetsi neemotokari mukugadzira zvikamu zvakaita semakepisi ekibhodhi, zvivharo zvemagetsi, uye zvikamu zvemota dashboard.

Nylon

Nylon kana polyamide ipurasitiki yakaderera-inokweshana polymer ine yakakwirira simba, makemikari, uye abrasion kuramba. Yayo yakanakisa mechanicha zvimiro, senge simba (76mPa), kusimba, uye kuomarara (116R), inoita kuti inyatsokodzera CNC machining uye nekuwedzera kuvandudza mashandisirwo ayo mumotokari uye chikamu chekurapa chikamu maindasitiri ekugadzira.

Pros

Yakanakisa michina zvinhu.

Iine simba repamusoro-soro.

Mari-inoshanda.

Iyo iri lightweight polymer.

Iyo inodzivirira kupisa uye makemikari.

Cons

Iine low dimensional kugadzikana.

Nylon inogona kutora mwando zviri nyore.

Inotarirwa kune yakasimba mineral acids.

Applications

Nylon ndeyepamusoro-inoita engineering thermoplastic inoshanda kune prototyping uye kugadzira zvikamu chaizvo mumaindasitiri ekurapa uye emotokari. Chikamu chinogadzirwa kubva kuCNC zvinhu chinosanganisira mabhengi, washers, uye machubhu.

Acrylic

Acrylic kana PMMA (Poly Methyl Methacrylate) inozivikanwa mupurasitiki CNC machining nekuda kwemaitiro ayo ekuona. Iyo plastiki polymer inoshanduka uye inoshingirira kukwenya, nekudaro mashandisirwo ayo mumaindasitiri anoda zvinhu zvakadaro. Kunze kweizvozvo, ine yakanaka kwazvo mechanicha zvimiro, inoonekwa mukuoma kwayo uye nekukanganisa kuramba. Nekuchipa kwayo, acrylic CNC machining yave imwe nzira kune epurasitiki polymers senge polycarbonate uye girazi.

Pros

Hairemi.

Acrylic yakanyanya makemikari uye UV inodzivirira.

Iine high machinability.

Acrylic ine high chemical resistance.

Cons

Haisi iyo inopesana nekupisa, kukanganisa, uye abrasion.

Inogona kutsemuka pasi pemutoro unorema.

Iyo haimirire kune chlorinated/aromatic organic substances.

Applications

Acrylic inoshanda mukutsiva zvinhu zvakaita se polycarbonate uye girazi. Nekuda kweizvozvo, inoshanda muindasitiri yemotokari kugadzira mapaipi akareruka uye mota chiratidzo chemwenje mavhavha uye mune mamwe maindasitiri ekugadzira solar panels, greenhouse canopies, nezvimwe.

POM

POM kana Delrin (zita rekutengesa) ipurasitiki inogadzirwa zvakanyanya CNC inosarudzwa nevakawanda CNC machining masevhisi nekuda kwesimba rayo repamusoro uye kuramba kupisa, makemikari, uye kupfeka / kubvarura. Kune akati wandei mamakisi eDelrin, asi maindasitiri mazhinji anovimba neDelrin 150 uye 570 sezvo iwo akatsiga.

Pros

Ndiwo anonyanya kugadzirwa pane ese CNC epurasitiki zvinhu.

Ivo vane yakanakisa makemikari kuramba.

Vane high dimensional kugadzikana.

Iyo ine yakakwira tensile simba uye kusimba, inovimbisa hupenyu hurefu.

Cons

Iine hutsika husina kumira kune acids.

Applications

POM inowana kushandiswa kwayo mumaindasitiri akasiyana siyana. Semuenzaniso, muchikamu chemotokari, inoshandiswa kugadzira zvikamu zvebhandi rechigaro. Indasitiri yemidziyo yekurapa inoishandisa kugadzira insulin zvinyoreso, nepo chikamu chezvigadzirwa zvevatengi chichishandisa POM kugadzira fodya yemagetsi nemamita emvura.

HDPE

High-density polyethylene plastiki ndeye thermoplastic ine yakanyanya kupikisa kusagadzikana uye makemikari anoparadza. Inopa yakanakisa mekiniki zvivakwa senge tensile simba (4000PSI) uye kuomarara (R65) pane yainotarisana nayo, iyo LDPE ichiitsiva mumashandisirwo ane zvinodiwa zvakadaro.

Pros

Ipurasitiki inochinjika inochinjika.

Iyo inopikisa zvakanyanya kushushikana uye makemikari.

Iyo ine yakanakisa ma mechanical properties.

ABS ine kusimba kwepamusoro, zvinoreva hupenyu hurefu.

Cons

Iyo ine urombo UV inodzivirira.

Applications

HDPE Iyo ine zvakasiyana-siyana zvekushandisa, zvinosanganisira prototyping, kugadzira magiya, mabheya, kurongedza, magetsi ekudzivirira, uye michina yekurapa. Yakanakira prototyping sezvo inogona kugadzirwa nekukurumidza uye zviri nyore, uye mutengo wayo wakaderera unoita kuti ive yakanaka yekugadzira akawanda iterations. Kunze kwezvo, chinhu chakanakira magiya nekuda kwekudzika kwayo coefficient yekupokana uye yakakwirira kupfeka kuramba, uye yemabhengi, nekuti inozvizora uye inodzivirira kemikari.

LDPE

LDPE ipurasitiki yakaoma, inochinjika polima ine yakanaka makemikari kuramba uye tembiricha yakaderera. Inoshandiswa zvakanyanya mune yekurapa chikamu chekugadzira indasitiri yekugadzira prosthetics uye orthotics.

Pros

Iyo yakaoma uye inochinjika.

Iyo inoshingirira mukuora zvakanyanya.

Zviri nyore kuisa chisimbiso uchishandisa nzira dzekupisa dzakadai sewelding.

Cons

Izvo hazvina kukodzera kune zvikamu zvinoda kupisa-kupisa.

Iine kuoma kwakaderera uye simba rekugadzirisa.

Applications

LDPE inowanzo shandiswa kugadzira magiya echivanhu uye zvinhu zvemuchina, zvinhu zvemagetsi senge insulators uye dzimba dzemidziyo yemagetsi, uye zvikamu zvine kupenya kana kupenya. Chii chimwe. yakaderera coefficient of friction, high insulation resistance, uye kusimba kunoita kuti ive chinhu chakanakira kushandiswa kwepamusoro-soro.

Polycarbonate

PC yakaoma asi isingaremi epurasitiki polymer ine kupisa retardant uye magetsi insulating zvivakwa. Kunge acrylic, inogona kutsiva girazi nekuda kwekujeka kwayo kwechisikigo.

Pros

Iyo inoshanda zvakanyanya kupfuura yakawanda engineering thermoplastics.

Iri pachena uye rinogona kutumira chiedza.

Zvinotora ruvara zvakanaka kwazvo.

Iine simba rakanyanya kusimba uye kusimba.

PC inopesana ne diluted acids, mafuta, uye magirisi.

Cons

Inodzikira mushure mekugara kwenguva refu kumvura inopfuura 60 ° C.

Inotarirwa nekupfeka hydrocarbon.

Ichaita yero nekufamba kwenguva mushure mekuratidzwa kwenguva refu kune UV mwaranzi.

Applications

Zvichienderana nechiedza chayo, polycarbonate inogona kutsiva girazi zvinhu. Saka, inoshandiswa mukugadzira magirazi ekuchengetedza uye maCD / maDVD. Kunze kweizvozvo, yakakodzera kugadzira midziyo yekuvhiya uye mabreaker circuit.

Plastic CNC Machining Methods

CNC plastiki chikamu machining inosanganisira kushandisa muchina unodzorwa nekombuta kubvisa chikamu chepurasitiki polymer kugadzira chigadzirwa chaunoda. Iyo inobvisa yekugadzira maitiro inogona kugadzira zviuru zvezvikamu zvine kushivirira kwakasimba, kufanana, uye iko kurongeka uchishandisa nzira dzinotevera.

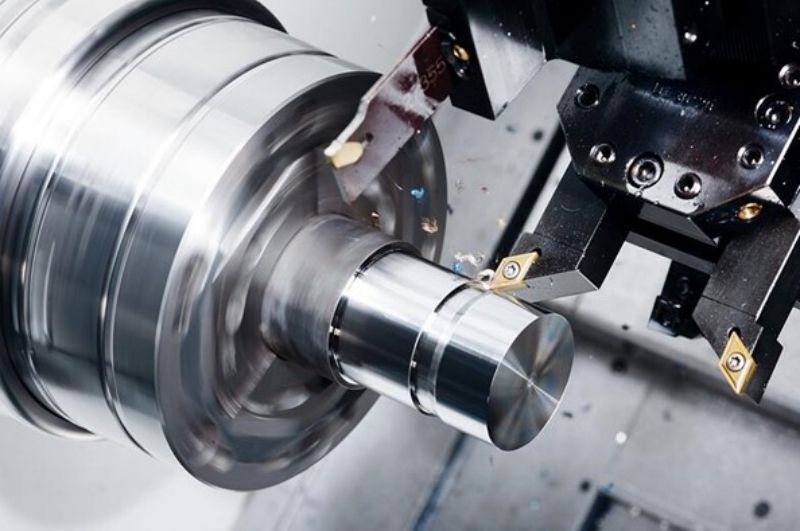

CNC Turning

CNC kutendeuka inzira yekugadzira iyo inosanganisira kubata iyo workpiece pane lathe uye nekuitenderedza ichipesana nechishandiso chekucheka nekutenderera kana kutendeuka. Kune zvakare akati wandei marudzi eCNC kutendeuka, anosanganisira:

Yakatwasuka kana cylindrical CNC kutendeuka kwakakodzera kucheka kukuru.

Taper CNC kutendeuka kwakakodzera kugadzira zvikamu zvine cone-senge maumbirwo.

Pane akati wandei nhungamiro yaunogona kushandisa mupurasitiki CNC kutendeuka, kusanganisira:

Ita shuwa kuti mativi ekucheka ane negative back rake kuderedza kukwesha.

Kucheka mipendero kunofanira kuva nekona huru yekuyamura.

Polisisa iyo workpiece pamusoro pepamusoro pekupedzisira uye yakaderedzwa kuvaka zvinhu.

Deredza chiyero chekudya kuti uvandudze kurongeka kwekucheka kwekupedzisira (shandisa chiyero chekudya che0.015 IPR chekucheka kwakashata uye 0.005 IPR yekucheka chaiko).

Gadzirisa iyo clearance, side, uye rake angles kune epurasitiki zvinhu.

CNC Milling

CNC kugaya kunosanganisira kushandisa chigayo chekucheka kubvisa zvinhu kubva paworkpiece kuti uwane chikamu chinodiwa. Kune akasiyana CNC milling michina yakakamurwa kuita 3-axis mill uye akawanda-axis mill.

Kune rimwe divi, 3-axis CNC milling muchina unogona kufamba mumatemo matatu ane mutsara (kuruboshwe kuenda kurudyi, kumashure nekudzoka, kumusoro uye pasi). Nekuda kweizvozvo, yakanyatsokodzera kugadzira zvikamu zvine magadzirirwo akareruka. Nekune rimwe divi, zvigayo zvakawanda-axis zvinogona kufamba mumatemo anopfuura matatu. Nekuda kweizvozvo, inokodzera CNC machining epurasitiki zvikamu zvine akaomarara geometries.

Pane akati wandei nhungamiro yaunogona kushandisa mupurasitiki CNC milling, kusanganisira:

Machine thermoplastic yakasimbiswa nekabhoni kana girazi ine kabhoni tooling.

Wedzera kumhanya kwe spindle nekushandisa ma clamps.

Deredza kushushikana kwepfungwa nekugadzira makona emukati akatenderedzwa.

Kutonhora zvakananga pane router kuparadzira kupisa.

Sarudza kumhanya kwekutenderera.

Debur epurasitiki zvikamu mushure mekugaya kuti uvandudze kupedzisa kwepamusoro.

CNC Drilling

Kuchera kwePlastiki CNC kunosanganisira kugadzira gomba muplastic workpiece uchishandisa chibooreso chakaiswa nechibhorani. Chibooreso ukuru uye chimiro zvinotaridza kukura kwegomba. Uyezve, inoitawo basa mukubvisa chip. Mhando dzedhiri rekudhiraivha dzaunogona kushandisa dzinosanganisira bhenji, rakatwasuka, uye radial.

Pane akati wandei nhungamiro yaunogona kushandisa mupurasitiki CNC kuchera, kusanganisira:

Ita shuwa kuti unoshandisa inopinza CNC drill bits kudzivirira kuisa kushushikana pane yepurasitiki workpiece.

Shandisa chibhorani chakakodzera. Semuyenzaniso, 90 kusvika 118° drill bit ine 9 kusvika 15° lip angle inokodzera most thermoplastic (ye acrylic, shandisa 0° rake).

Ita shuwa iri nyore chip ejection nekusarudza chaiyo drill bit.

Shandisa inotonhorera sisitimu yekudzikisa yakawanda inogadzirwa panguva yekugadzira machining.

Kubvisa iyo CNC drill pasina kukuvara, shuwa kuti kudzika kwekuchera kuri kushoma katatu kana kana. chibooreso dhayamita. Zvakare, deredza mwero wekudya kana chibooreso chave kuda kubuda muzvinhu.

Zvimwe kune Plastic Machining

Kunze kweCNC plastiki chikamu machining, mamwe maitiro ekukurumidza prototyping anogona kushanda sedzimwe nzira. Zvakajairika zvinosanganisira:

Jekiseni Molding

Iyi inzira yakakurumbira yekugadzira misa yekushanda nepurasitiki workpieces. Jekiseni kuumba kunosanganisira kugadzira mold kubva kualuminium kana simbi zvichienderana nezvinhu zvakaita sehupenyu hurefu. Mushure mezvo, purasitiki yakanyungudutswa inopinzwa mugomba re mold, inotonhorera, uye inoita chimiro chaunoda.

Plastic jekiseni molding inokodzera zvese prototyping uye kugadzira kwezvikamu chaizvo. Kunze kweizvozvo, inzira inodhura-inoshanda yakakodzera zvikamu zvine yakaoma uye yakapusa dhizaini. Uyezve, zvikamu zvakaumbwa zvejekiseni hazvidi rimwe basa kana kurapwa kwepamusoro.

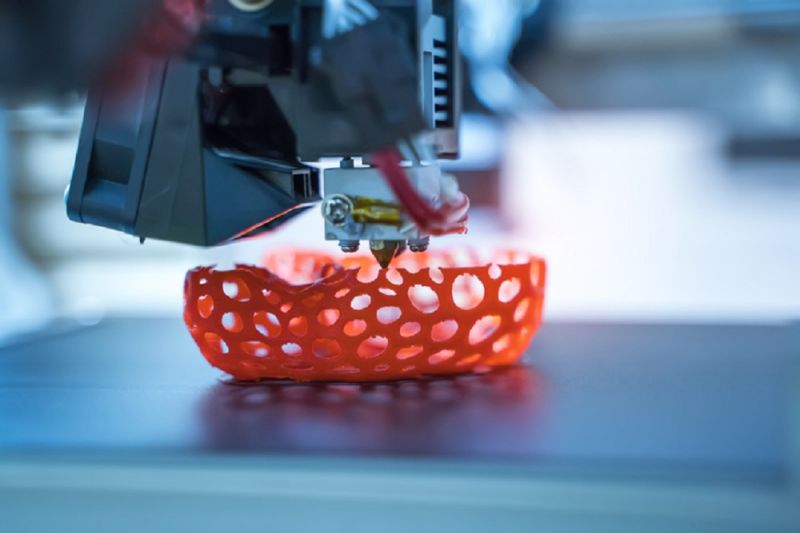

3D Kudhinda

3D kudhinda ndiyo inonyanya kushandiswa prototyping nzira inoshandiswa mumabhizinesi madiki. Iyo yekuwedzera yekugadzira maitiro inokurumidza prototyping chishandiso chinosanganisira matekinoroji akadai seStereolithography (SLA), Fused Deposition Modeling (FDM), uye Selective Laser Sintering (SLS) inoshandiswa kushanda pa thermoplastics senaironi, PLA, ABS, uye ULTEM.

Imwe neimwe tekinoroji inosanganisira kugadzira 3D dhijitari modhi uye kuvaka inodiwa zvikamu layer ne layer. Izvi zvakafanana nepurasitiki CNC machining, kunyangwe ichiunza kushomeka kwezvinhu, kusiyana neiyo yekupedzisira. Uyezve, inobvisa kudiwa kwekushandisa uye inonyanya kukodzera kugadzira zvikamu zvine dhizaini yakaoma.

Vacuum Casting

Vacuum casting kana polyurethane/urethane casting inosanganisira masilicon molds uye resin kuita kopi ye master pateni. Iyo yekukurumidza prototyping maitiro akakodzera kugadzira epurasitiki nemhando yepamusoro. Uyezve, makopi anoshanda mukuona mazano kana kugadzirisa matambudziko ekugadzira.

Industrial Applications yePlastiki CNC Machining

Plastiki CNC machining inoshanda zvakanyanya nekuda kwemabhenefiti akadai sekurongeka, kunyatsoita, uye kushivirira kwakasimba. Zvakajairika maindasitiri mashandisirwo eiyo maitiro anosanganisira:

Indasitiri yezvokurapa

CNC machining epurasitiki ari kushanda pari zvino mukugadzira zvikamu zvemuchina zvekurapa senge nhengo dzeprosthetic uye moyo yekugadzira. Yayo yakakwirira dhigirii yekurongeka uye kudzokorora inobvumira kuti isangane neyakaomesesa kuchengetedza zviyero zvinodiwa neindasitiri. Uyezve, kune zviuru zvezvinhu zvingasarudzwa, uye zvinogadzira zvimiro zvakaoma.

Automotive Components

Vese vagadziri vemota uye mainjiniya vanoshandisa Plastiki CNC machining kugadzira chaiyo-nguva yemotokari zvikamu uye prototypes. Plastiki inoshandiswa zvakanyanya muindastiri mukugadzira tsika cnc epurasitiki zvikamu zvakaita semadhibhodhi nekuda kwekureruka kwayo, izvo zvinoderedza kushandiswa kwemafuta. Uyezve, plastiki inoshingirira mukuora uye kupfeka, izvo zvinhu zvakawanda zvemotokari zvinosangana nazvo. Kunze kweizvozvo, plastiki inoumbwa kuita maumbirwo akaomarara zviri nyore.

Zvikamu zveAerospace

Aerospace chikamu kugadzira kunoda nzira yekugadzira ine yakanyanya kurongeka uye kushivirira kwakasimba. Nekuda kweizvozvo, indasitiri inosarudza CNC machining mukugadzira, kuyedza, uye kuvaka akasiyana aerospace machini zvikamu. Zvishandiso zvepurasitiki zvinoshanda nekuda kwekukodzera kwazvo zvimiro zvakaoma, simba, huremu uye makemikari akakwira, uye kudzivirira kupisa.

Electronic Indasitiri

Iyo indasitiri yemagetsi inofarirawo CNC epurasitiki machining nekuda kwekunyanya kwayo uye kudzokorora. Parizvino, maitiro aya anoshandiswa kugadzira CNC-machini epurasitiki emagetsi zvikamu senge waya akavharirwa, mudziyo keypads, uye LCD skrini.

Nguva Yekusarudza Plastiki CNC Machining

Kusarudza kubva kune akawanda ekugadzira epurasitiki maitiro anokurukurwa pamusoro apa anogona kuve akaoma. Nekuda kweizvozvo, pazasi pane mashoma ekufunga anogona kukubatsira iwe kusarudza kana epurasitiki CNC machining ndiyo iri nani maitiro epurojekiti yako:

Kana Plastiki Prototype Dhizaini ine Tight Tolerance

CNC plastiki machining ndiyo nzira iri nani yekugadzira zvikamu zvine madhizaini anoda kushivirira kwakasimba. Iyo yakajairika CNC milling muchina unogona kuwana kushivirira kwakasimba kweanosvika 4 μm.

Kana Plastic Prototype Inoda Hunhu Hwepamusoro Pedzisa

CNC muchina unopa yepamusoro-yemhando yepamusoro kupedzisa kuita kuti ive yakakodzera kana purojekiti yako isingade imwe yekuwedzera yekupedzisa maitiro. Izvi zvakasiyana ne 3D kudhinda, iyo inosiya ma layer panguva yekudhinda.

Kana Plastic Prototype Inoda Zvinhu Zvinokosha

Plastiki CNC machining inogona kushandiswa kugadzira zvikamu kubva kwakasiyana siyana epurasitiki zvinhu, kusanganisira izvo zvine akakosha zvimiro zvakaita seyepamusoro-tembiricha kuramba, kusimba kwepamusoro, kana kukwirira kwemakemikari kuramba. Izvi zvinoita kuti ive sarudzo yakanaka yekugadzira prototypes ine hunyanzvi zvinodiwa.

Kana Zvigadzirwa Zvako Zviri muKuedza Stage

CNC machining inotsamira pamhando dze3D, dziri nyore kuchinja. Sezvo nhanho yekuyedza inoda kugara ichigadziriswa, CNC machining inobvumira vagadziri uye vagadziri kugadzira anoshanda epurasitiki prototypes kuyedza uye kugadzirisa dhizaini kukanganisa.

· Kana Iwe Uchida Economical Option

Kufanana nedzimwe nzira dzekugadzira, epurasitiki CNC machining akakodzera kugadzira zvikamu zvinodhura. Purasitiki inodhura zvishoma pane simbi nezvimwe zvinhu, zvakadai semakombusi. Uyezve, kutonga kwenhamba dzekombuta kwakaringana, uye maitiro acho akakodzera dhizaini yakaoma.

Mhedziso

CNC plastiki machining inzira inogamuchirwa zvakanyanya mumaindasitiri nekuda kwekurongeka kwayo, kumhanya, uye kukodzera kugadzira zvikamu zvine kushivirira kwakasimba. Ichi chinyorwa chinotaura nezve akasiyana CNC machining zvinhu zvinoenderana nemaitiro, maitiro aripo, uye zvimwe zvinhu zvinogona kubatsira purojekiti yako.

Kusarudza iyo chaiyo machining tekinoroji inogona kuve yakaoma kwazvo, zvichiita kuti iwe uende kunze kune yepurasitiki CNC service provider. KuGuanSheng isu tinopa epurasitiki epurasitiki CNC machining masevhisi uye anogona kukubatsira iwe kugadzira zvikamu zvakasiyana zve prototyping kana chaiyo-nguva yekushandisa zvichienderana nezvaunoda.

Tine akati wandei epurasitiki machira akakodzera CNC machining ane yakaomesesa uye yakakwenenzverwa sarudzo maitiro. Uyezve, timu yedu yeinjiniya inogona kupa hunyanzvi hwekusarudza zvinhu uye zano rekugadzira. Isa dhizaini yako nhasi uye utore maquotes ipapo uye yemahara DfM ongororo pamutengo wemakwikwi.

Nguva yekutumira: Nov-13-2023