Chikamu chekugadzira chiri pakati pemaindasitiri ane simba. Nhasi, kune kusundidzira kusingadzoreki kukwidziridza kurongeka kwese uye kurongeka uye maitiro senge waya EDM anounza chaizvo izvo hazvisi zvishoma pane shanduko yeindasitiri.

Saka, chii chinonzi Wire EDM chaizvo, uye nei ichionekwa semutambo-shanduko kune chikamu chekugadzira? Chinyorwa chinotevera chinotarisa kune izvo zvekutanga zvehunyanzvi hwekugadzira iyi ine maapplication mumaindasitiri akasiyana.

Nhanganyaya Pfupi kune Wire EDM

Wire Electrical Discharge Machining (EDM) yakapayona muma1940 nemasayendisiti maviri eSoviet akatanga kunyura simbi nekubuda kwemagetsi. Iyo tekinoroji yakaona kufambira mberi kwakakosha muma60s uye 80s, ichiwedzera kutengeserana mukugadzira. Pakazosvika makore ekuma90, nekuvandudzwa kweIT uye CNC, michina ye EDM yewaya yakave yakawanda yemakomputa, ichiwedzera kugona kwavo uye nemazvo.

Nhasi, Wire EDM yakakosha mumaindasitiri akaita seAerospace, Automotive, uye Medical, anozivikanwa nekupa madhizaini akaomarara uye mafomu akaoma asingaenzaniswi nemaitiro echinyakare machining.

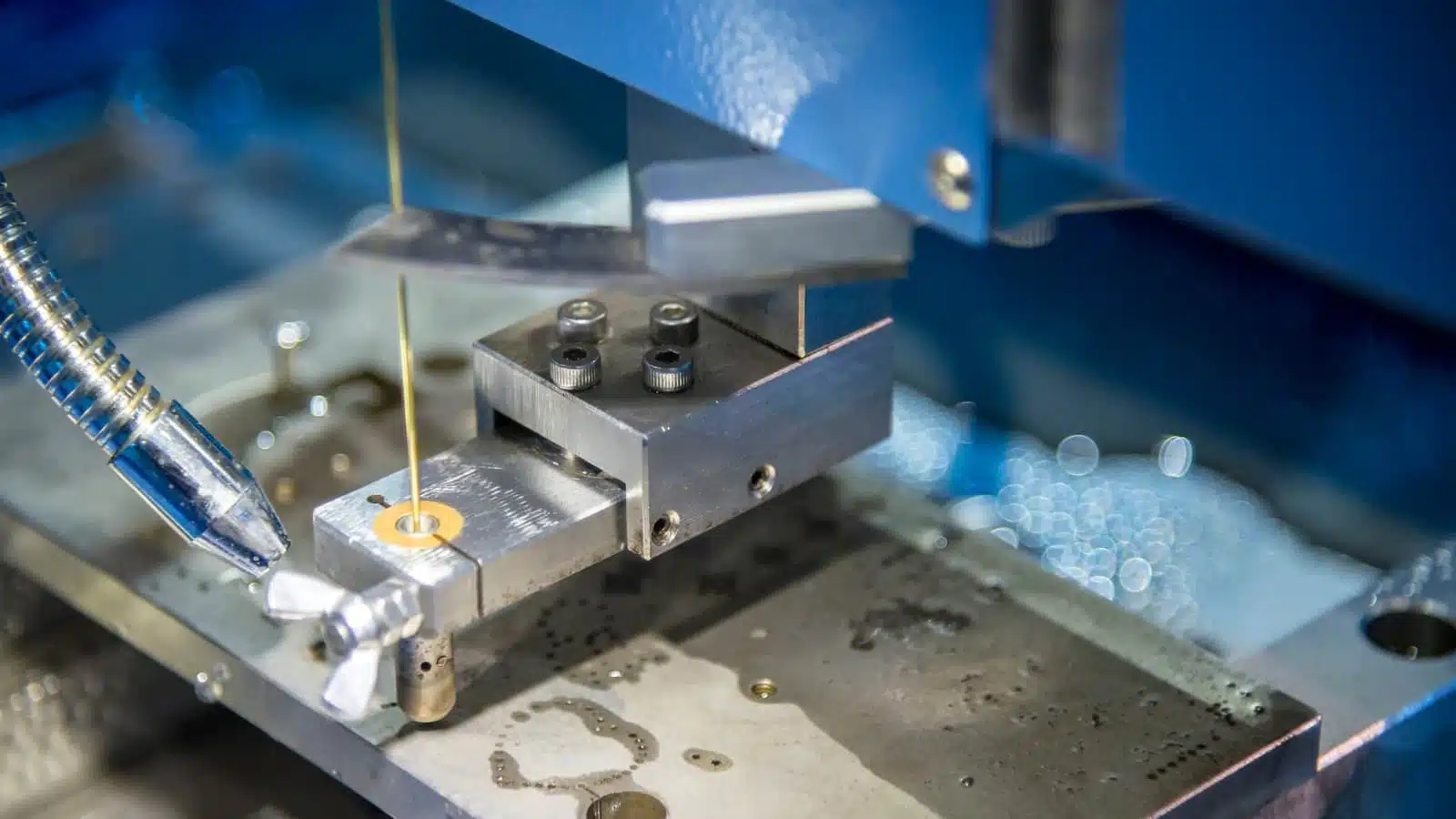

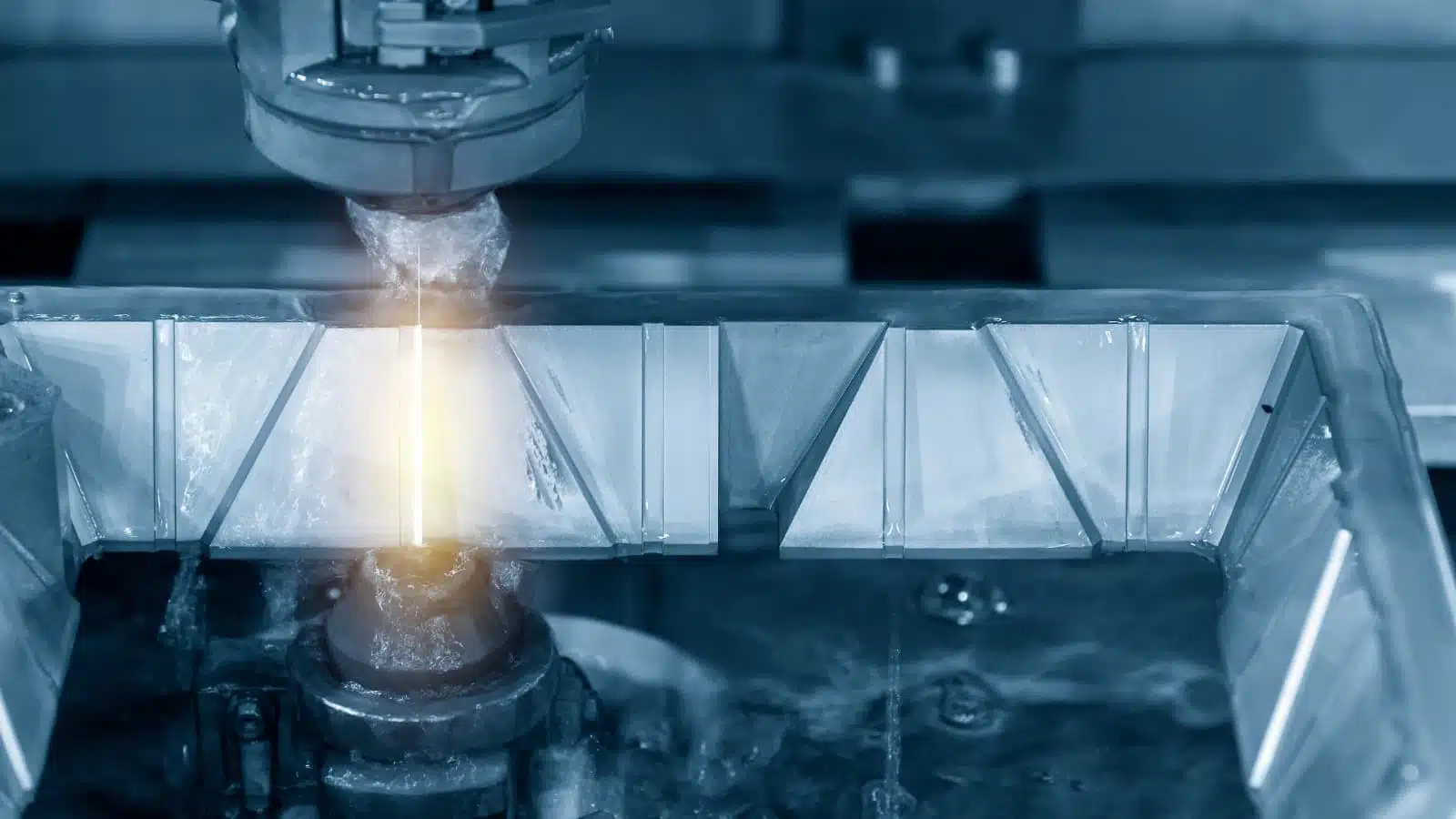

Iyo Wire EDM Maitiro

Wire Electrical Discharge Machining (EDM) inzira chaiyo inoshandisa inodzorwa magetsi kunyungudutsa zvidimbu zvidiki zvebasa rekushanda. Iyo electrode yewaya, inowanzo gadzirwa nendarira kana zinc-yakavharidzirwa zvinhu, inogadzira iyi spark uye inofamba munzira yakafanosetwa. Kubatsira kwayo? Inoshanda pasina kubata kwemuviri, kudzivirira chero kukuvadzwa kana mamaki pane ese ari maviri workpiece uye chishandiso.

Iyo EDM Inoshanda sei

EDM inonamatira pane simba rinopisa kubva pakubuda kwemagetsi. Kubuda uku kunopisa iyo workpiece kusvika pakunyungudika kwayo, ichigadzira madiki eplasma chiteshi. Aya machani, kazhinji ane hukuru hwe micrometer, anogona kupera nekukurumidza.

Iyo EDM process inoitika mune dielectric medium, kazhinji deionized mvura. Iyi mvura inotonhorera iyo workpiece uye inobvisa vaporized zvinhu, zvichibatsira mukuenderera mberi machining.

Kukosha kweWaya Electrode

Kuita sesese mucheki uye conductor, waya electrode yakakosha. Yakaputirwa nezvinhu zvakaita sendarira kana zinc, inopikisa maitiro pakupisa kwakanyanya. Inodzorwa nekombuta, inova nechokwadi chekucheka kwakaringana nekukanganisa kushoma uye kunyatsojeka.

Tolerances for Wire EDM

Kucheka waya ndeimwe yemaitiro chaiwo ekugadzira aripo. Saka, kushivirira kwakasimba hakusi kwechinyakare pazviri. Iko kushivirira chaiko kunoenderana nezvakati wandei zvinosanganisira kuomesesa kweprojekiti, kugona kugadzira, uye hunyanzvi hwemushandisi.

Nekudaro, iyo yakajairwa uye inogamuchirika kushivirira ndiyo indasitiri bhenji inotevedzwa nevazhinji vagadziri.

Kushivirira Kwakakwana uye Kushivirira Kwakanaka

Kushivirira kwakajairika

Linear Tolerances: Kazhinji kubva ± 0.005 kusvika ± 0.001 inches (0.127 kusvika 0.0254 mm), zvichiratidza kutsauka kunobvumidzwa kwezvinhu zvakaita semaburi, slots, kana profiles.

Hole Diameter Tolerances: Kazhinji pakati pe ± 0.0005 kusvika ± 0.001 inches (0.0127 kusvika 0.0254 mm), kuve nechokwadi kuti maburi emuchina anogara mukati medhayamita yakatsanangurwa.

Kushivirira Kwakanaka

Linear Tolerances: Inowana humbowo padanho remicron, kazhinji kubva ± 0.0002 kusvika ± 0.0001 inches (0.0051 kusvika 0.00254 mm), yakakosha kune zvikumbiro zvinoda kunyatsojeka.

Hole Diameter Tolerances: Ranges kubva ± 0.0001 kusvika ± 0.00005 inches (0.00254 kusvika 0.00127 mm), inoratidzira Wire EDM yakasarudzika chaiyo.

Zvinhu Zvinokonzera Kushivirira muWaya EDM

Wire EDM yakakurumbira nekuda kweiyo micron-level chaiyo, ichiita kuti ive yakanaka kune yakaoma kunzwisisa. Nekudaro, iko kurongeka kwayo hakuna kugadzikiswa uye kunotsamira pane akati wandei zvinhu:

• Kugadzikana Kwemashini: Muchina wakagadzikana unova nechokwadi chekugadzirisa zviri nani mukucheka zviito.

• Wire Hunhu uye Diameter: Kuchena kwayo, dhayamita, uye hunhu hwemagetsi zvinopesvedzera machining maitiro. Optimal results inoda chiyero pakati pewaya kunaka uye dhayamita.

• Workpiece Material: Nepo zvimwe zvinhu zviri nyore kuwana muchina, zvinhu sarudzo anofanira kuenderana Anwendung zvinodiwa.

• Flush Conditions: Kuyerera kwe dielectric medium, kunokanganisa hutano hwekugadzira machining, rubatsiro mukubvisa zvinhu, kushandiswa kwemagetsi kusingagumi, uye kupisa kunobudirira.

•Machina Calibration uye Maintenance: Kugona kwemuchina kwakakosha. Michina yepamusoro ine vashandi vane hunyanzvi yakakosha kuti uwane kushivirira kwakanyanya.

• Thermal Stability: Kuti uchengetedze kunyatsoziva kweWire EDM, kudzorwa kwemagetsi arcs kwakakosha. Kusagadzikana kwekushisa kunogona kukanganisa kururamisa, kusimbisa kukosha kwemamiriro ezvinhu anowirirana.

Zvishandiso Zvinonyanya Kukodzera Kucheka Wire

Ferrous Metals

Simbi isina ngura

Inobatanidza kusimba neakanakisa magetsi conductivity. Kugona kwayo kuramba ngura kunoita kuti ive chinhu chinotsvakwa mumaindasitiri akasiyana. Muchirevo chekugadzira, kuenderana kwayo nekwakajeka uye kwakadzama dhizaini kunomira pachena.

Tool Steel

Inozivikanwa nekuomeswa kwayo, simbi yemidziyo ndiyo musana wezvishandiso zvakawanda zvinorema-basa uye mativi chaiwo. Kuoma kwayo kwekuzvarwa, kana ichisanganiswa nemagetsi ayo, inoita kuti ive mumiriri weiyo yakaoma kunzwisisa uye kupinza kwenguva refu.

Carbon Steel

Mutambi anochinja-chinja mudura resimbi, kabhoni simbi, kunyangwe isingaite machina kupfuura mamwe ayo, inogona kugadzirwa kusvika pakukwana nesarudzo dzemagetsi emagetsi uye ma paramita ekushanda. Kukwanisa kwayo kusanganisa nekuita kwayo kunoita kuti ive chikafu mumaindasitiri mazhinji.

Alloy Steel

Kubatanidzwa kwezvinhu, kuita kwesimbi yealloy ndeye tapestry yezvikamu zvayo. Zvichienderana nekusanganiswa kwayo kwakasarudzika, inogona kupa simba, kusimba, uye machinability, zvichiita kuti ive sarudzo ine simba kune akasiyana maapplication.

Zvisina-Ferrous Metals

Titanium

Kazhinji inodaidzwa kuti 'space-age metal', kusimba kwetitanium uye nzvimbo yakakwira yekunyungudika zvinounza matambudziko mukugadzira kwakajairika. Nekudaro, kana yakachekwa nematurusi echokwadi, inoburitsa madhizaini akaomarara uye akatsiga, zvichiita kuti ive inofarirwa neaerospace uye maindasitiri ekurapa.

Aluminium

Iyo inodiwa yesimbi isina kuremerwa, aluminium inopembererwa nekunaka kwayo kwemagetsi conductivity uye malleability. Iyo haingope kusununguka kwekugadzira asi zvakare inovimbisa simba pasina mutoro wehuremu, zvichiita kuti ive yakakosha mumaindasitiri kubva pakufambisa kuenda pakurongedza.

Mhangura

Conductor par excellence, mhangura iri pamwoyo pezvakawanda zvemagetsi nemagetsi zvinoshamisa. Yayo chaiyo yakatsvuka-orenji hue yakasanganiswa nekugona kwayo kuumbwa kuita zvinhu zvakadzama inoita kuti ive yakakosha muzvinhu zvese kubva kumagetsi kusvika kuhunyanzvi hwekushongedza.

Brass uye Bronze

Aya alloys, anopenya mumatoni avo egoridhe, haasi ezve aesthetics. Mamiriro avo emagetsi anoyemurika anovaita kuti vaende-kune zviwanikwa zvezvikamu zvinosangana nerunako, senge muzvishongo zvakashongedzwa kana zvikamu zvemagetsi zvakagadzirwa zvakanaka.

Key Applications of Wire EDM mu Modern Engineering

Wire EDM machining iri kuwana traction nekuda kwekuita kwayo kwakasiyana-siyana mukubata zvinhu zvakasiyana-siyana uye kugona kwayo kuzadzisa zvakadzama uye kushivirira kwakasimba, zvichiita kuti ive yakakosha mukugadzira kwemazuva ano. Heano maapplication matatu ekutanga:

Precision Parts Manufacturing

Sarudzo yakajairika yekugadzira yakakwirira-chaiyo zvikamu zvine kushivirira kwakasimba. Inokunda mukugadzira zvimiro zvakaoma, zvinyorwa zvakanaka, uye zviduku muzvinhu zvakasiyana-siyana.

Maindasitiri akadai seaerospace, zvekurapa, zvemotokari, uye zvemagetsi zvinotsamira paWaya EDM kugadzira zvinhu zvakakosha senge magiya, nozzles, zvinobatanidza, uye mold dzakaoma kunzwisisa.

Tool uye Die Production

Wire EDM inobatsira mukugadzira molds, kufa, uye hunyanzvi hwekushandisa, kugovera kune maitiro kubva mukuumbwa kwejekiseni kusvika pakutsika. Kugona kweiyo nzira mukusimudzira zviyero uye kuveza makona akapinza kunovimbisa premium mhando uye kufanana mukugadzirwa kwakakura.

Prototype Development

Kune inokurumidza uye chaiyo prototyping, mainjiniya nevagadziri vanokwevera vakananga Wire EDM. Izvi zvinokurumidzisa dhizaini yekusimbisa uye yakaoma nhanho yekuyedza.

Prototypes chiseled kuburikidza neWire EDM padhuze girazi yekupedzisira chigadzirwa, ichisimbisa kukosha kwayo mukutenderera kwechigadzirwa.

Tichifunga nezvesimba rayo munzvimbo idzi dzepakati, Wire EDM's chaiyo uye yakaringana hunyanzvi inowedzerwa zvakanyanya mumaindasitiri mazhinji.

•Medical Device Manufacturing

• Electronics uye Micro-zvikamu

•Aerospace uye Aviation

•Zvishongo uye Kugadzira wachi

•Automotive Industry

•Energy Sector

•Mold and Die Repair

Nguva yekutumira: Zvita-12-2023